「Cutting」 × 「Turnig」

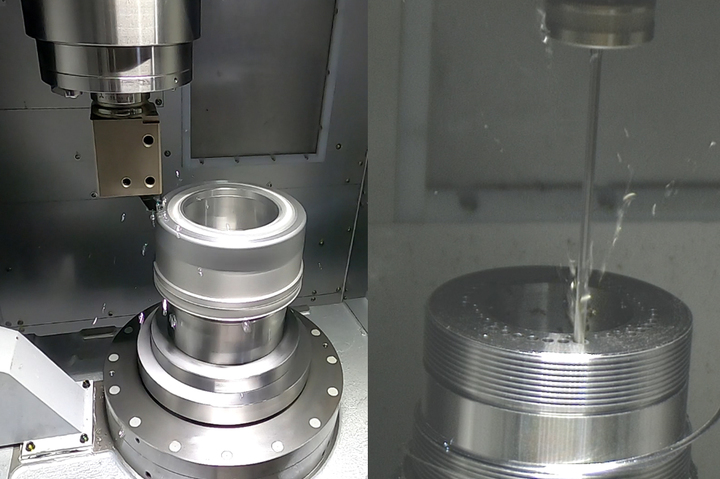

A multi-tasking machine with a turning function added to the bedless machining center.

Integrating cutting process and turning process in one machine realizes the intensive high-efficiency production by preventing unclamp/clamp defects between processes and reducing process capability management.

Equipped with a newly developed φ80mm curvic-clamp spindle that supports turning, ensuring high accuracy in rotational positioning when using the lathe turning tool.

A-axis for indexing and C-axis table for turning are standard specification. The C-axis table for turning is available in a 3,000min-1 high-speed specification and a 1,000min-1 in the lineup.

This machine is capable of indexing 5-axis and can be used for producing a wide range of parts such as steel parts and motor housing with an aluminum cooling layer.

Main features

-

-

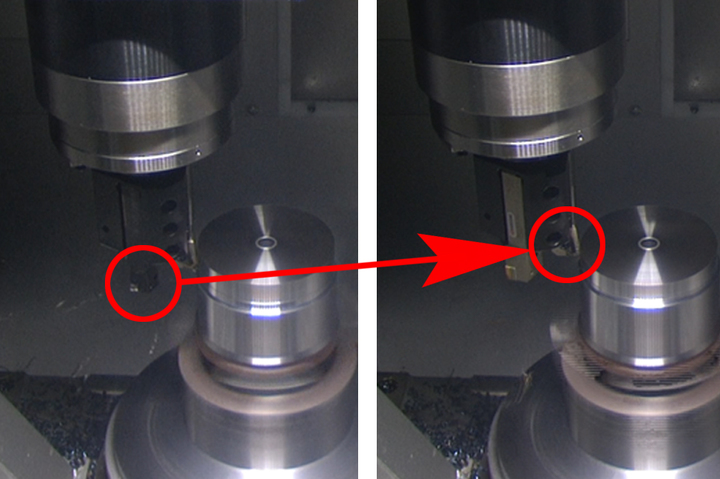

High speed tool change

By attaching multiple bites on the holder, the tool indexing (every 5 degrees) can be performed by rotating the spindle without ATC movement.

-

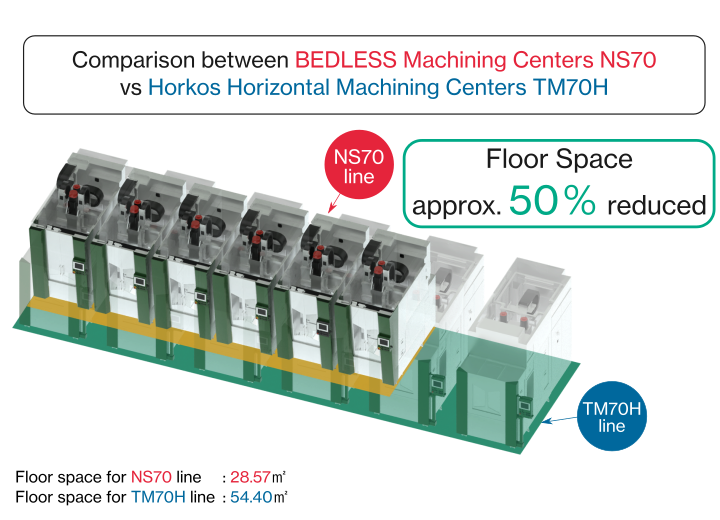

Space Saving

by consolidating components that requires adjustment such as hydraulic and pneumatic valves on the front and rear of the machine, maintenance from the side of the machine is not required, when placing multiple machines, a layout with an inter-machine pitch of 150 mm is possible, and it makes the line configuration with the minimum space is possible. Therefore, the workpiece transportation distance is short, which leads to shortening of transportation time and reducing the cost.

-

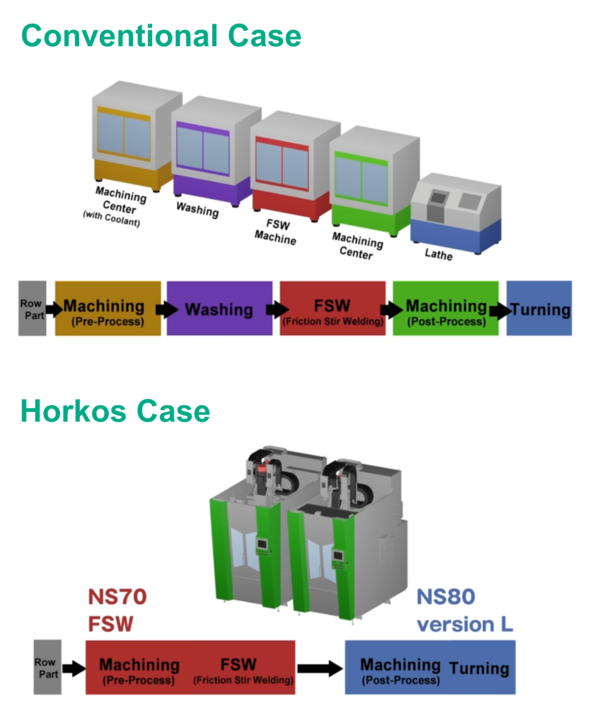

Process Integration

When combined with 【NS70 FSW】, a FSW multifunctional machine that is with FSW function added to a BEDLESS machining center, integrated high efficient production can be realized.

Main Specifications

- Travel (X, Y, Z)

- 500mm、450mm、500mm

- Rapid traverse rate

- 62m/min-1

- Tool holder

- HSK-A63、HSK-T63

- Footprint

- 1,450mm x 3,380mm

- Max. rotation speed

- 12,000min-1

- Tool storage capacity

- 30

「Cutting」 × 「Turnig」

Cutting and turning on one machine