「Semi Dry Cutting」 × 「FSW」

A production line type FSW multi-function machine with FSW(Friction Stir Welding) function added to the bedless machining center.

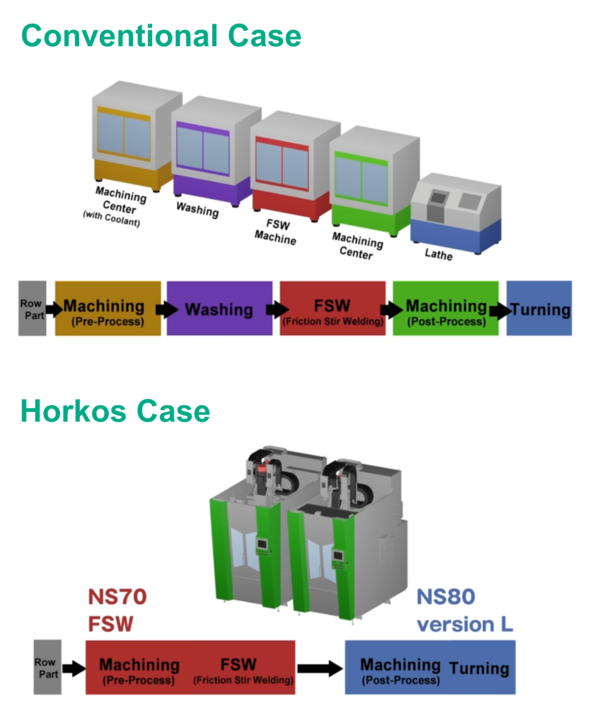

In combination with semi dry cutting (iMQL), Pre-process of FSW => FSW to FSW => deburring and finishing after FSW can be performed in a single chucking.

With the combination of various tables, this space-saving multi-function machine is suitable for battery cases, transmission cases,motor cases with cooling layers, etc.

Integrating these processes eliminates quality variations between processes and bonding defects caused by clamp distortion during unclamping/clamping the workpiece.

Main features

-

-

Semi dry cutting (iMQL)

-

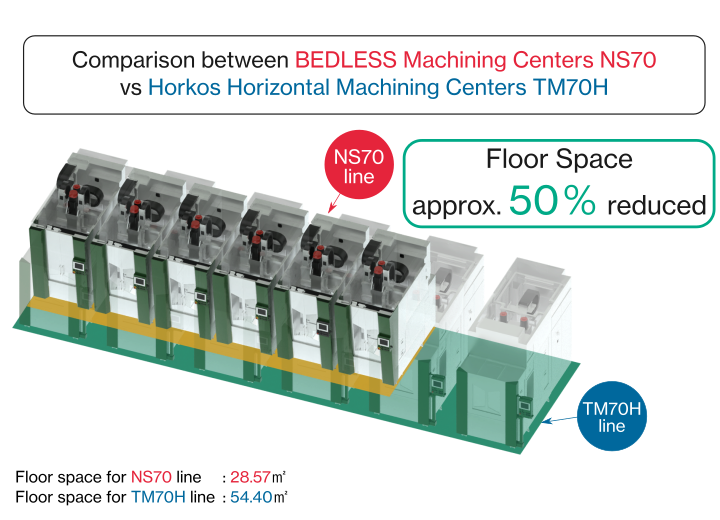

Space Saving

by consolidating components that requires adjustment such as hydraulic and pneumatic valves on the front and rear of the machine, maintenance from the side of the machine is not required, when placing multiple machines, a layout with an inter-machine pitch of 150 mm is possible, and it makes the line configuration with the minimum space is possible. Therefore, the workpiece transportation distance is short, which leads to shortening of transportation time and reducing the cost.

-

Process Integration

When combined with 【NS80 version L】, a multitasking machine that is with lathe function added to a BEDLESS machining center, integrated high efficient production can be realized.

Main Specifications

- Travel (X, Y, Z)

- 500mm、450mm、500mm

- Rapid traverse rate

- 62m/min-1

- Tool holder

- HSK-A63

- Footprint

- 1,450mm x 2,830mm

- Max. rotation speed

- 12,000min-1

- Tool storage capacity

- 16

FSW(Friction Stir Welding)