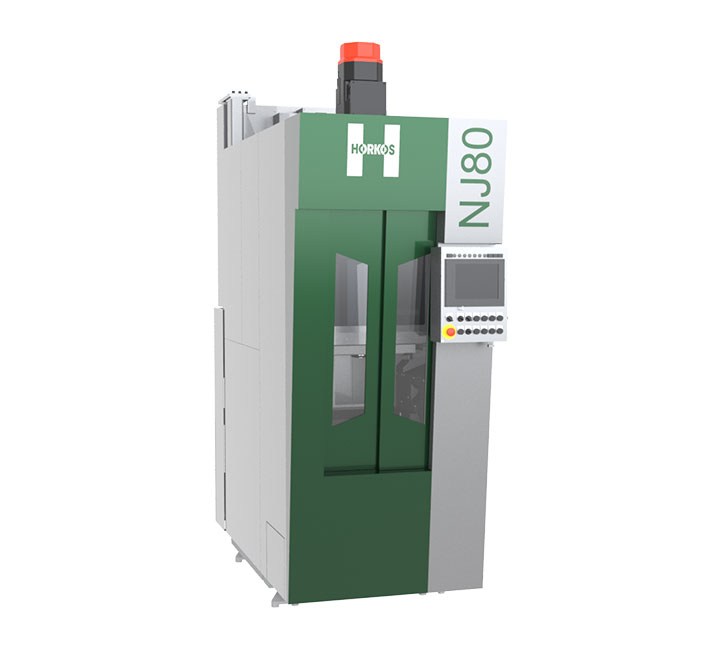

「Super Space-Saving」 x 「Heavy Cutting」

Heavy-duty, high-efficiency bedless machining center equiped with φ80mm spindle in 990mm wide super compact body.

Ideal for machining parts with difficult-to-cut materials such as engines, reduction gears and drive train parts.

Main features

-

-

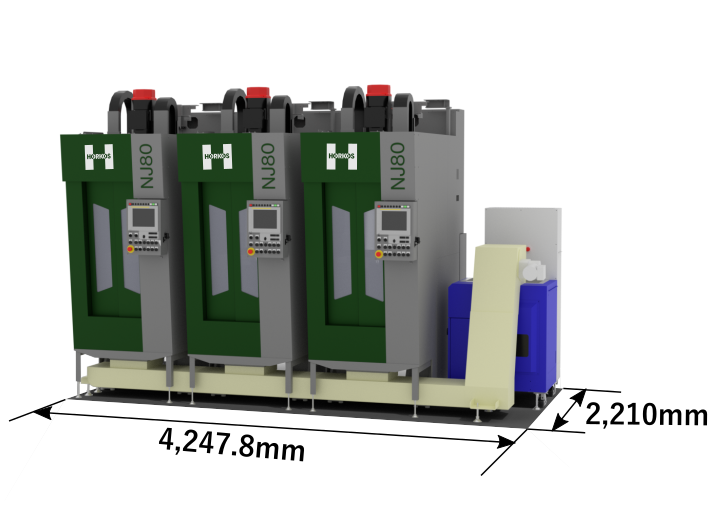

Proposal to Reduce Installation Space by Half

By utilizing the space under the fixtures, it is possible to handle the end face machining of long shaft parts such as axle shafts, which were conventionally machined with horizontal machines, and production can be performed in 50% of the installation space (compared to our conventional horizontal machines), which will significantly change the factory layout.

In addition, by consolidating components that require adjustment such as hydraulic and pneumatic valves on the front and rear of the machine, maintenance from the side of the machine is not required. When placing multiple machines, the layout can be made with a pitch of 150mm between machines, and it makes the line configuration with minimum space is possible. Therefore, loading/unloading distance is short, which leads to shortening of loading/unloading time and reducing the cost.

-

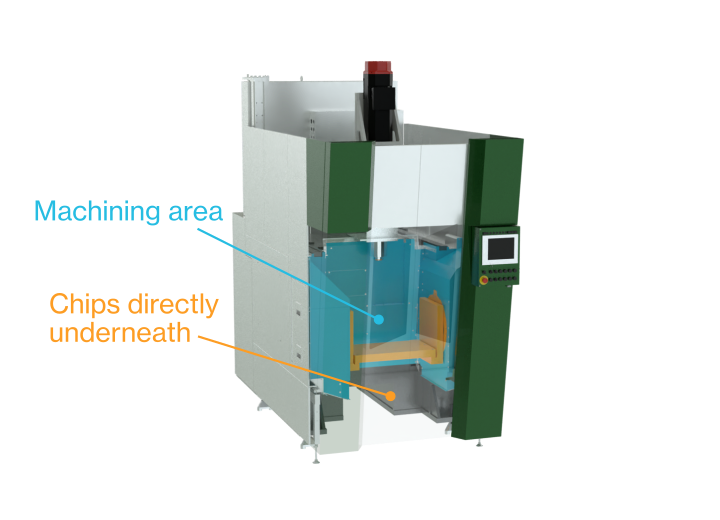

Best Chip Evacuation

The bedless structure with no structural parts underneath the machining area allows chips generated during machining to be discharged directly outside the machine, greatly improving problems caused by chips.

Main Specifications

- Travel (X, Y, Z)

- 200mm、250mm、350mm

- Rapid traverse rate

- 40m/min-1

- Tool holder

- HSK-A50

- Footprint

- 990mm x 2,170mm

- Max. rotation speed

- 8,000min-1

- Tool storage capacity

- 12

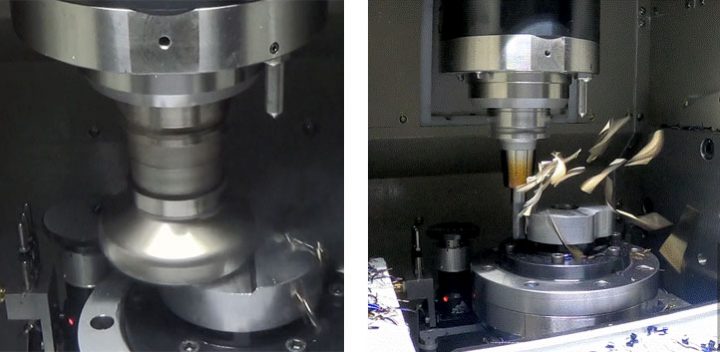

Super high efficiency machine for heavy cutting

Material:S45C