Cutting, turning, and skiving are possible on a single machine

Achieve high-efficiency gear machining with skiving on a high-rigidity bedless machining center®! With optional specifications, turning operations are also possible, allowing multiple processes to be consolidated into a single machine. This setup significantly reduces space requirements and machining time, boosting productivity.

Main features

-

-

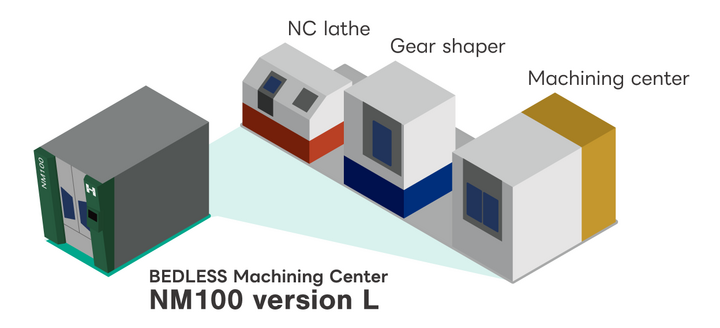

Process Integration

By consolidating multiple processes into a single machine, significant space reduction and shortened processing times can be achieved, resulting in highly efficient production on gear machining lines.

Additionally, with HORKOS's unique bedless structure, it is possible to further minimize the space required when introducing a multi-tasking machine.

Main Specifications

- Travel (X, Y, Z)

- 500mm、500mm、550mm

- Rapid traverse rate

- 40m/min-1

- Tool holder

- HSK-T100

- Footprint

- 1,800mm x 3,750mm

- Max. rotation speed

- 6,000min-1

- Tool storage capacity

- 16

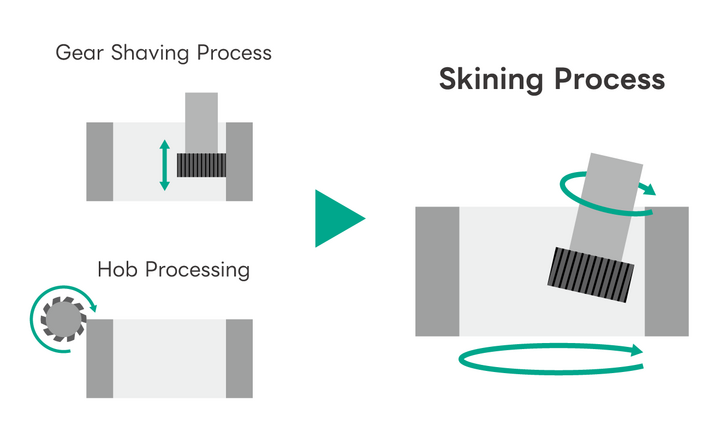

Achieving High-Efficiency Gear Machining with Skiving

The bedless machining center® NM100 version L is equipped with skiving functionality, enabling both gear machining and cutting processes on a single machine. Additionally, with optional specifications, turning operations are also possible. The table's maximum rotation speed of 3000 min-1reduces machining time.